by Neil Currie

The hazardous nature of the industries that we operate in, like the oil, gas and chemical industry, dictates that our processes and systems are required to be safe, robust and reliable. At the centre of this is a common thread: risk assessment. When identifying hazards and choosing controls there is one key question to answer: are we getting it right?

As a Subject Matter Expert (SME) on our Training & Services Team, I have been lucky enough to travel extensively and assist our clients with Control of Work solutions all over the world. Originally from a high voltage electrical background, I have had a career spanning 30 years working in a diversity of engineering and operational roles in high risk environments including oil & gas, petrochemical, pharmaceutical engineering, confined space entry and working with explosives. As a Chartered Health & Safety Professional I have used my skills and experience to develop a strong understanding of safety management systems which is well utilised in my current role.

Risk free?

As we know, it is virtually impossible to work risk free. We also know it is a moral, legal and financial obligation to manage all risks presented at work, whether they are low risk routine activities in the office or complex hazardous tasks carried out at remote locations. Failure to identify hazards correctly in the past or poor selection of controls has resulted in catastrophe and as such safety in the workplace has evolved from initially being seen as a burden to being an integral part of how we operate with risk assessment at the forefront of our safe systems.

Personal thing

Seen by some as a dark art risk assessment, is actually something we do every day, but when done correctly by competent staff can be used to examine the workplace to identify exactly what can cause us harm in order to evaluate what can be done to control it. This methodology works for simple and complex tasks, but identifying hazards correctly requires a high level of risk awareness that comes with training and experience and it goes without saying that there is a great deal of responsibility assigned to the task. As such, in my experience, personnel who are involved in the process of assessing risk, especially in hazardous industries, are familiar with the workplace or task and do so in the knowledge that they are ultimately making decisions and choices that directly affect the workforce and whether working alone or as part of a team that responsibility and accountability ensures that a logical, systematic and thorough job is carried out.

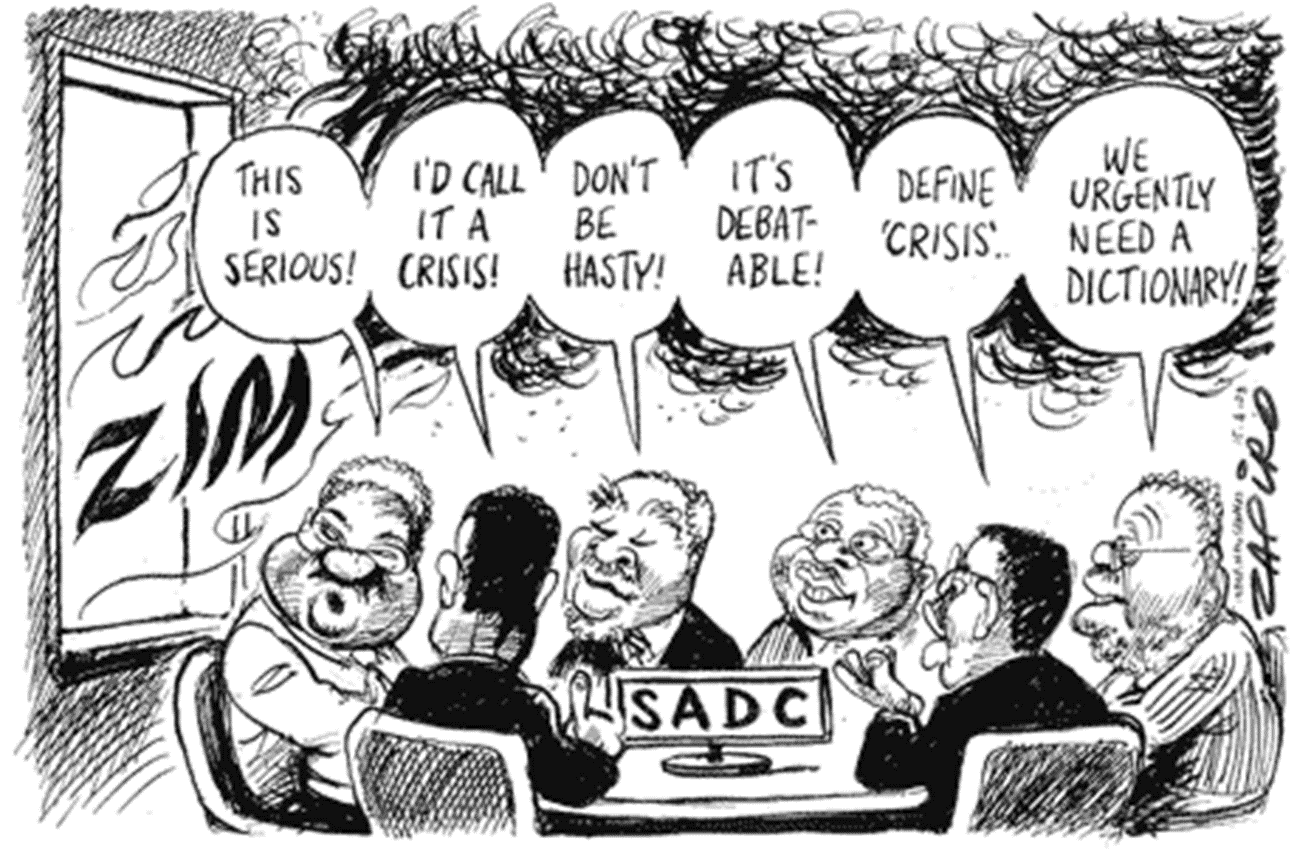

How we interpret hazards and risk is also a very personal thing and as such one person’s view on risk is very different to another, this is called perception and it is very important that it is taken into account when determining an appropriate level of risk assessment. For every person who is risk aware there is also another who is risk averse and the selection of the appropriate person for the job is key. Pick the wrong guy and it could be a disaster!

Safe system of work

The process of assessing risk is fairly simple and follows a logical routine of identifying hazards, identifying who may be harmed and how, evaluating the risk and implementing controls, monitoring and reviewing the situation and adapting to change. There is excellent guidance available on the subject of risk assessment and when implemented within a digital control of work solution and used by competent and considerate personnel, it can make a real difference.

Routine low risk activities are typically covered by simple qualitative risk assessments. Usually completed by one competent person this takes into account an assessment of the overall risk by taking an objective view of the task, identifying relevant hazards and implementing suitable and sufficient controls to make it safe. Typical tasks covered by this would include simple scaffold erection, visual inspections on equipment or painting handrails.

Higher risk activities such as confined space entries, complex lifts or working overboard warrant a higher level of rigour when assessing risk and as such are usually conducted as a subjective team based activity. As the tasks are high risk, each step is analysed to identify hazards and evaluate risks by using a detailed quantitative scale for establishing existing risk, with no controls in place and residual risk, having applied all reasonably practicable control measures.

Working with high voltage electricity required respect for this hidden and extremely dangerous hazard and my experience of planning and executing work safely involved all levels of risk assessment and has been transposed to my current role on the SME team providing best practice advice, training and support and I am extremely proud to be a part of the eVision family.

Robust risk assessment systems ensures that tasks can only begin when appropriate controls are confirmed as in place and when built into a safe system of work that integrates the permit system and isolation management clients are provided with the tools to provide a safe workplace where staff are able to conduct their daily duties with minimal risk or incident. That is getting it right!

The author, Neil Currie is Subject Matter Expert at eVision Industry Software.